MIL-PRF-87895A(USAF)

2.4

Order of precedence.

In the event of a conflict between the text of this document and the references cited herein, the

text of this document takes precedence. Nothing in this document, however, supersedes

applicable laws and regulations unless a specific exemption has been obtained.

3.

REQUIREMENTS

3.1

First article.

When specified (see 6.2), a sample shall be subjected to first article inspection in accordance

with 4.2.

3.2

Materials.

The material shall be composed of two parts: a base, Part A, and a plasticizer, Part B. Part A

shall consist of a pure amorphous polypropylene hot melt thermoplastic, conforming to the

requirements specified in table I, and Part B shall consist of an Isobutylene-butene copolymer

(commonly known as polybutenes) conforming to the requirements specified in table II.

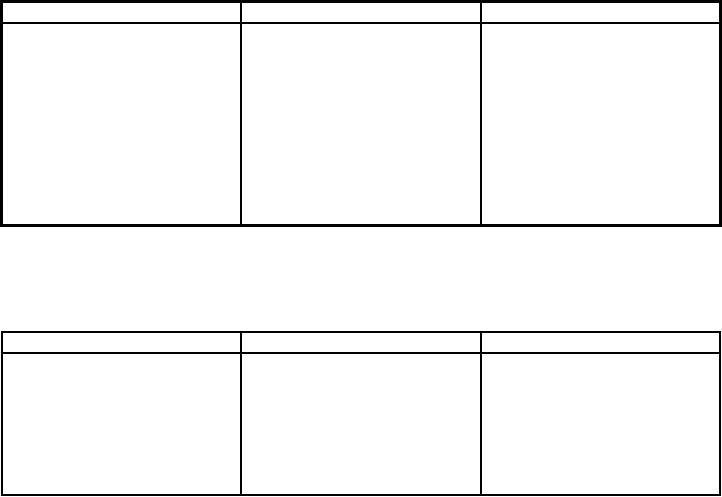

TABLE I. Part A, base characteristics.

CHARACTERISTIC

REQUIREMENT

INSPECTION

Specific gravity at 73°F

.86±.04

4.5.1

Viscosity at 375°F

3500±500 centipoises

4.5.2

295±5°F

Softening point

4.5.3

500°F min

Flash point

4.5.5

500°F min

Fire point

4.5.5

Volatile content

.5% max

4.5.6

Ash content

.5% max

4.5.7

Acidity

.1% max

4.5.8

-40°F min

Glass transition temperature

4.5.13

TABLE II. Part B, plasticizer characteristics.

CHARACTERISTIC

REQUIREMENT

INSPECTION

.91 ±.04

Specific gravity

4.5.1

Viscosity at 210°F

3200 ±200 centipoises

4.5.2

450°F min

Flash point

4.5.5

500°F min

Fire point

4.5.5

Acidity

0.1% max

4.5.8

-65°F min

Glass transition temperature

4.5.13

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business