MIL-PRF-87895A(USAF)

3.2.1

Formulation.

Parts A and B shall be combined in a ratio of 65 ±.1 Part A to 35 ±.1 Part B. The materials

shall be combined via melt blending at a temperature of 350°F. Blending shall be sufficient to

produce a homogeneous mixture.

3.2.2 Product characteristics.

The compound (combined material) when prepared shall consist of a hot melt thermoplastic

and conform to the requirements specified in table III when tested in accordance with 4.5.

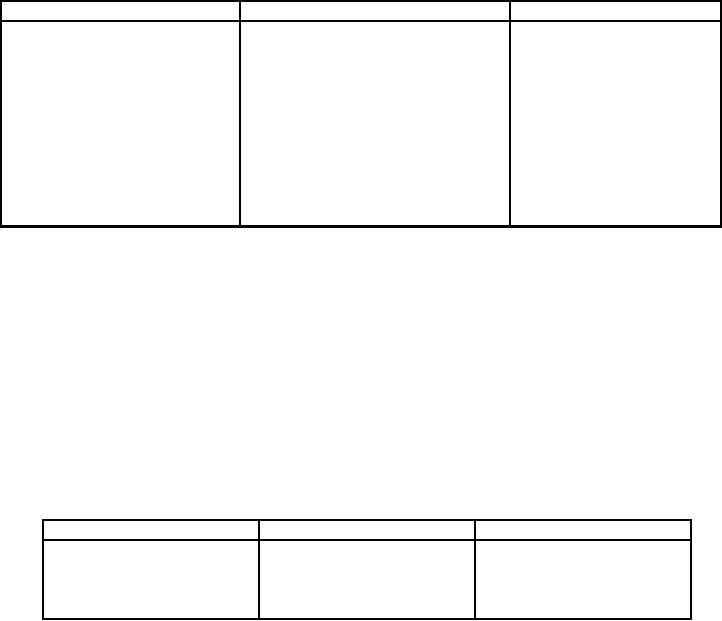

TABLE III. Compound characteristics.

CHARACTERISTIC

REQUIREMENT

INSPECTION

.86 ±.04

Specific gravity

4.5.1

Viscosity at 375°F

1500 ±500 centipoise

4.5.2

220°F min

Softening point

4.5.3

200 gm/60 sec/0°C (32°F) 5 min

Penetration

4.5.4

100 gm/5 sec/25°C (77°F) 15 min

50 gm/5 sec/45°C (115°F) 90 max

500°F min

Fire point

4.5.5

450°F min

Flash point

4.5.5

-65°F max

Glass transition temperature

4.5.13

3.2.3

Chemical, electrical and mechanical properties.

3.2.3.1 Flexibility.

A dried film of the compound on a metal panel shall show no chipping, scaling, or cracking

when tested as specified (see 4.5.9).

3.2.3.2 Chemical requirements.

The compound shall conform to the chemical requirements specified in table IV.

TABLE IV. Chemical requirements.

REQUIREMENT

MAXIMUM VALUE

INSPECTION

Volatile content

.5%

4.5.6

Ash content

.5%

4.5.7

Acid content

.1%

4.5.8

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business